Peter Bowyer

Livestock farmers can significantly reduce their straw bedding fixed costs and improve the straw bed by introducing a straw spreading machine in preference to a turbine chopper, according to results from a Harper Adams University (HAU) study.

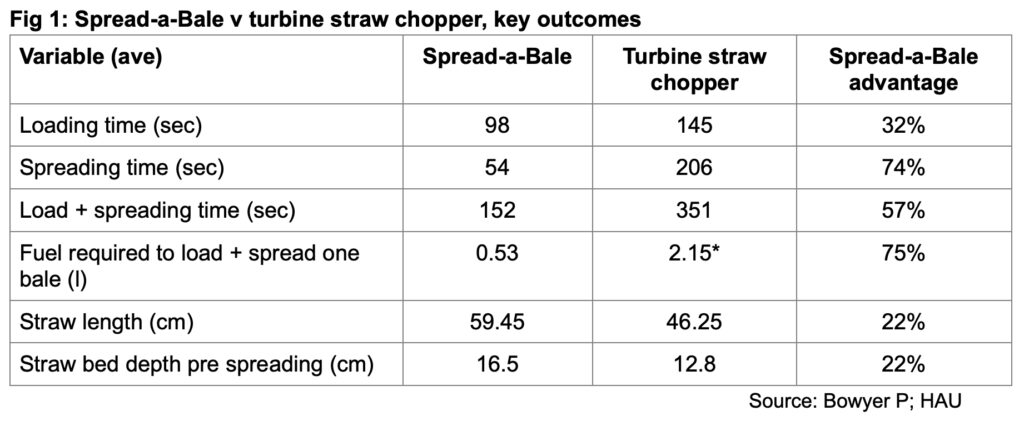

Time to spread one rectangular bale by Spread-a-Bale amounted to less than one minute, almost four times faster than the turbine straw chopper, while loading time was cut by a third according to the study findings compiled by BSc (Hons) agriculture student, Peter Bowyer. Fuel required to load and spread one bale was reduced by 75%, while Spread-a-Bale left the straw over 20% longer resulting in a deeper bed. See Fig 1.

The study was designed to investigate if the type of straw spreader used to bed up growing heifers in HAU’s dairy unit affected bedding characteristics and the run time of the machine used to power the straw spreader. The shed was bedded with fresh straw three times a week during the six-week study period with one of the two straw spreading machines – Spread-a-Bale and a turbine straw chopper.

“The total time required to both load and spread one straw bale recorded by the turbine straw chopper, driven by a 150hp tractor, was twice that of the Spread-a-Bale, a result that not only confirmed Spread-a-Bale made for significant cost savings but also the potential to improve efficiencies and in turn, reduce emissions,” comments Peter Bowyer.

“The study also concluded that the two machines influenced both bedding quality and bed longevity. Spread-a-Bale is designed to spread straw with rotating blades which maintain straw length – an average 59.45cm was recorded, and it left a significantly fluffier bed, well suited to nesting. In comparison, the turbine chopper literally chopped the straw with a knifed auger before blowing it through a spout via a flywheel into the bed, leaving straw almost 25% shorter in length. Furthermore, the study concluded the beds produced by Spread-a-Bale were deeper and they lasted longer.”

Spread-a-Bale’s Michael Hughes adds: “This HAU trial confirms the consistent trends reported by livestock farmers since we launched our unique straw spreading machine over two decades ago. The trial also endorses Spread-a-Bale’s significant advantages over tractor drawn turbine machines, significantly reducing time and subsequently fuel, which in turn makes for monetary savings.”

Swapping a turbine chopper for a Spread-a-Bale Midi machine and Mathew Ramsden found similar trends to the HAU study. “We’re annually finishing 350 head of dairy bred beef cattle; bulls are bedded up every day and heifers every other with up to five rectangular bales.

“Spreading straw is now a lot simpler job. Bale loading time has been reduced by approximately 20% and since the machine requires only one front end loader, we’ve been able to cut one tractor out of the operation, and we’ve saving on the diesel it used,” explains Mathew who farms a mixed unit at Kaimflat, Kelso with his parents, Martin and Janet.

“Since Spread-a-Bale literally spreads the straw – it doesn’t chop it, we’re using about 20% less and while we continue to use all of our own straw, it means we have less to buy in.

“Another main advantage is less dust – it used to sit in the air in the buildings and the cattle were breathing it in. Then on windy days, the chopped straw would blow all over the place, whereas nowadays we can boom the machine over the feed fence, and its spreads direct into the pens and the straw lasts longer.”

He adds: “We’ve also found straw spreading is nowadays a lot quieter, the cattle are more content and we’ve a lot tidier workplace.”

Recent Comments